Graphic industry, film and foil industry

Many business groups are found in the graphics industry, including the film / foil industry, etc.

Calender rolls in silicone or EPDM with the advantage:

- Special non-stick silicone, so that the film does not stick to the roll.

- Fiber filled EPDM is ground to RA so that the film is felted.

- High-quality non-stick silicone, finely ground without marquise on the roller surface, so that the film gives a clear picture.

- DOP-resistant silicone for PVC sheets.

- Correct adhesion in connection with the adjustment of the roll surface, so that the rubber does not escape from the core under high pressure.

- electrically conductive and antistatic mixtures in silicone / EPDM / NBR / etc.

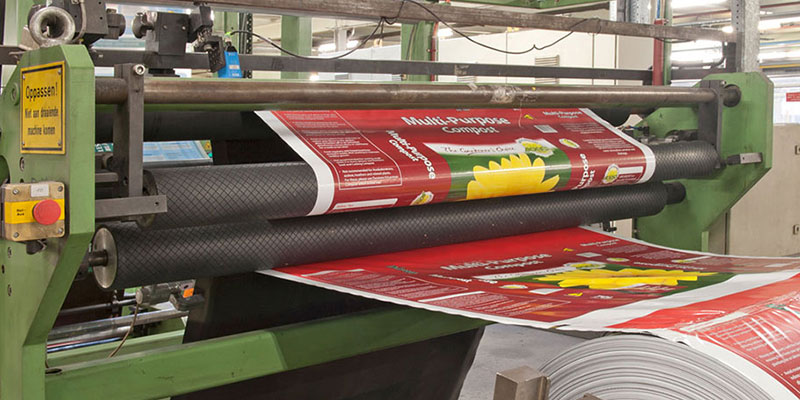

Laminating rolls

We supply laminating rollers with a special non-stick silicone, so that the film does not stick to the roller and the film is laminated evenly.

Paint rollers

We supply ink rollers with a precisely sharpened RA value and tolerances. The clean and pure rubber compounds result in a clean paint.

Pressure rollers

We supply pressure rollers which are ground within the impact resistance, so that the pressing is straight.

Transport / Extrusion rollers

Transport / extrusion rollers are supplied with wear-resistant rubber compounds to limit the wear and shrinkage of these rollers, thereby extending service life.

Spreader Rolls

Spreader rolls are supplied with the right blades that are ground / grooved so that the film can not fold.

Ink rollers

For the graphics industry, we supply ink rollers / color sleeves, which ensure the best results through clean rubber compounds and precise grinding work (correct diameter and roughness / RA). Counterpressure rollers and sleeves are provided with rubber compounds of the right hardness. Partly due to the pure grinding work, the folding of paper and foil is prevented.

Other examples of roles are:

Corona pretreatment rollers with high electrical insulation values. The Corona pre-treatment rollers are very resistant to hot and hot air, have excellent surface quality and are very resistant to aging and wear. Stretch rollers in electrically conductive / antistatic rubber quality with good resistance to high temperatures and wear.

flexography

Flexographic printing is one of the most commonly used printing processes for the label, packaging and film industry.

The most important feature of flexible printing plates is the resistance to printing inks and solvents. The flexo industry uses a wide variety of inks, both solvent inks and water-based inks. Other important features that need to be taken into account include color transfer, hardness and longevity.

Egberts Rubber also supplies: doctor blades, doctor blade chamber seals and cutting supplies.

Gravure

Roll upholstery for the publishing, packaging and film industries. Properties include excellent resistance to high stress and mechanical stress, excellent ink transfer, good solvent resistance and, if desired, electrically conductive / antistatic.

Egberts Rubber offers high-quality solutions for every position where a coated roll appears in the printing process.

Inform about the possibilities, delivery times and prices!

More information?

Call +31 546 86 11 82 or mail us: info@egberts-rubber.nl